Nimonic 80A, Alloy 80A is a wrought, age-hardenable nickel-chromium alloy, used for gas-turbine components (blades, rings, discs), bolts, tube supports in nuclear generators, exhaust valves in internal combustion engines and has many other offshore/marine, automotive and electrical applications.

What is Nimonic 80A grade steel?

NIMONIC® alloy 80A, UNS N07080, 2.4952, 2.4631 is a wrought, age-hardenable nickel-chromium alloy(are primarily composed of nickel and chromium.). Alloy 80A is similar to alloy 75 but made precipitation hardenable by additions of aluminium and titanium. Alloy 80A has good corrosion and oxidation resistance and high tensile and creep-rupture properties at temperatures to 815ºC (1500ºF). Alloy 80A is used for gas-turbine components (blades, rings, discs), bolts, tube supports in nuclear generators, exhaust valves in internal combustion engines and has many other offshore/marine, automotive and electrical applications.

Products Form:

Chemical Composition

| Grade | Chemical composition WT % | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Ti | Al | Cu | Fe | Co | B | Zr | |

| Nickel Alloy 80A | 0.10 | 1.0 | 1.0 | 0.005 | 0.015 | 18-21 | Bal | 1.8-2.7 | 1.0-1.8 | 0.2 | 3.0 | 2.0 | 0.008 | 0.15 |

| Nimonic 80A | 0.04-0.1 | 0.10 | 1.0 | 0.005 | 0.005 | 18-21 | min 65 | 1.8-2.7 | 1.0-1.8 | 0.2 | 1.5 | 1.0 | 0.008 | - |

| UNS N07080 | 0.1 | 1.0 | 1.0 | 0.045 | 0.015 | 18-21 | Bal | 1.8-2.7 | 1.0-1.8 | 0.2 | 3.0 | 2.0 | 0.008 | |

| AFNOR NF NC 20TA | 0.04-0.10 | 1.0 | 1.0 | 0.02 | 0.015 | 18-21 | Bal | 1.8-2.7 | 1.0-1.8 | 0.2 | 3.0 | 2.0 | 0.008 | |

| 2.4952, NiCr 20 TiAl | 0.04-0.10 | 1.0 | 1.0 | 0.02 | 0.015 | 18-21 | min 65 | 1.8-2.7 | 1.0-1.8 | 0.2 | 1.5 | 1.0 | 0.008 | |

| HEV 5 | Bal | |||||||||||||

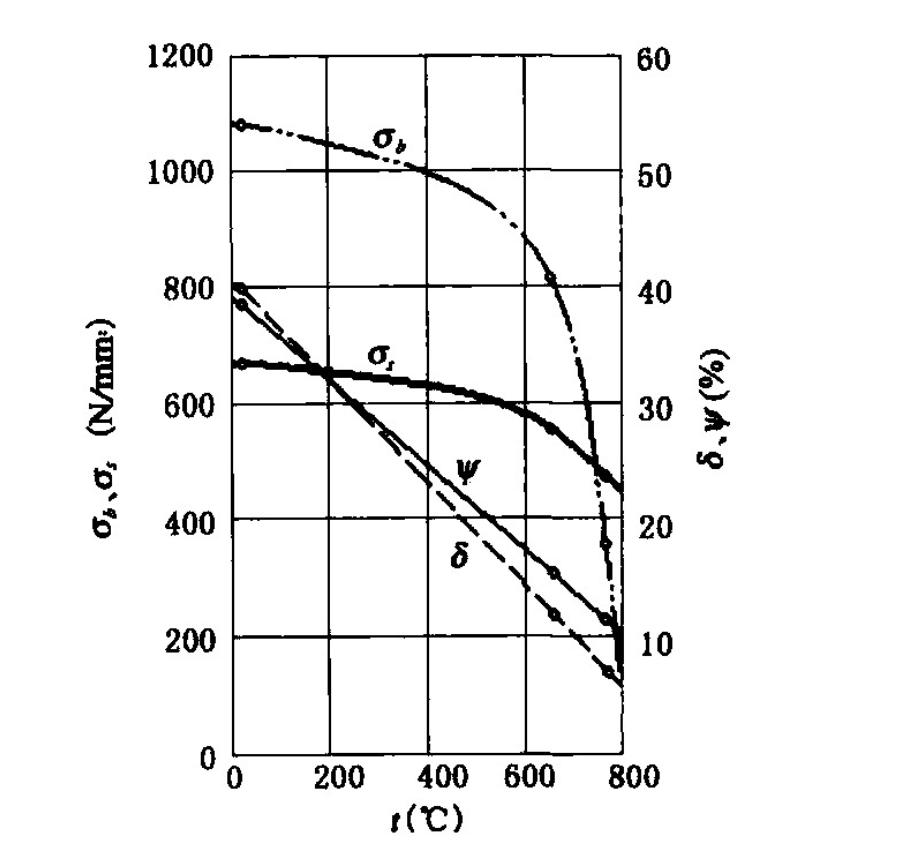

Mechanical Properties

Nimonic 80A Mechanical properties

- Tensile strength Rm MPa: 1000-1300

- Yield Strength Rp MPa: Min 600

- A %: 12

- Hardness, HB 310-400

- Impact Charpy, min 20 J

Tensile diagram for Nimonic 80A

Physical Properties

- Density

- g/cm3: 8.19

- lb/in3: 0.296

- Melting Range: 1320-1365°C / 2410-2490°F

- Magnetic Properties

- Mass Susceptibility: 5.85 x 10-6 at 1000 gauss

- Volume Susceptibility: 4.78 x 10-5 at 1000 gauss

- Magnetic Permeability: 1.000601 for 200-2000 oersted

Heat Treatment

- Solution annealing: 1050°C – 1080°C / 8h / air

- Stabilization: 845°C ± 10°C / 24h / air

- Precipitation hardening: 700°C ± 10°C / 16h / air

Nimonic 80A Bolt Heat Treatment

- Step 1: The hot-rolled or forged bars of Nimonic 80A alloy to be manufactured bolts are subjected to solution heat treatment at 1080 ° C ~ 1100 ° C, and the holding time is: bars with a diameter of less than 60mm are kept for 2 to 5 hours, and air is cooled to room temperature; The bar is kept warm for 5-8 hours, and the oil is cooled to room temperature;

- Step 2: After the bar in step 1 is processed into finished bolts that meet the specification requirements, vacuumize the closed workpiece chamber until the vacuum degree is not lower than 1×10-5Pa, and then pass AlCln gas into the workpiece chamber to make the workpiece The pressure in the chamber is not lower than 0.4MPa. Finally, place the bolts in an AlCln atmosphere and heat them to 750°C~760°C for chemical-aging heat treatment. The holding time is: 4~6 hours for bolts with a diameter smaller than 60mm, and bolts with a diameter larger than 60mm The bolts are kept warm for 6~8 hours; high-purity argon is used to cool to room temperature; the AlCln atmosphere is a mixed gas composed of AlCl, AlCl2 and AlCl3, which is made by pure aluminum powder and ammonium chloride powder according to 1: (2~6) Prepared by heating to 650°C after mixing the mass ratio

A Nimonic 80A alloy bolt heat treatment process according to claim 1, characterized in that, in step 2, the purity of high-purity argon is not less than 99.99%, and the cooling rate is not less than 10°C/min by controlling the flow rate .

The bolt heat treatment process of a kind of Nimonic 80A alloy material according to claim 1 or 2, is characterized in that, this heat treatment process can obtain the aluminum content that the mass ratio is not less than 15% in the depth of 2 μm on the surface of the bolt, and the hardness is not less than 320HB ; The yield strength at room temperature is not less than 740MPa; the thickness of the oxide film at 850℃/100h in static air is not more than 0.1μm, reaching the complete anti-oxidation level.

Thermal Properties

| Properties | Metric | Imperial |

|---|---|---|

| Thermal expansion co-efficient (@20-100°C/68-212°F) | 12.7 µm/m°C | 7.06 µin/in°F |

| Thermal conductivity | 11.2 W/mK | 77.7 BTU.in/hrft².°F |

Welding Properties

Nimonic 80A alloy can be welded using conventional welding techniques such as gas-tungsten arc welding, shielded metal-arc welding and submerged-arc welding.

Machining Properties

Nimonic 80A alloy can be machined using conventional machining techniques used for iron-based alloys. This alloy work-hardens during machining.

What is Nimonic 80A equivalent to?

Nimonic 80A, Alloy 80A, UNS N07080, 2.4952, UNS N07080, BS 3076, HR1, HR401, HR601, HR201, ASTM B637, DIN 17742, DIN17754, NC 20 TA, NiCr 20 TiAl, 2.4952