Stainless and Special Steels for

Energy & Power Generation

- Steel grades

- Get certificate

- Get membership

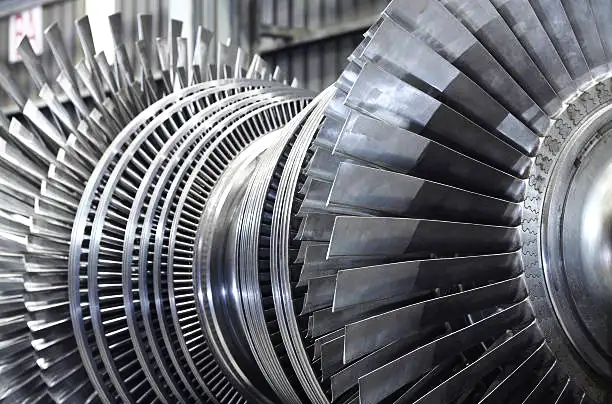

Steel for Turbine Blade, Vane

UNS S4500, XM-25, GTD 450, Alloy C450, GE B50A789; UNS S4200, AISI 422, AISI 616, B4B, SUH616, 10705BP, 10705BAA/10705AG, 10705BU, 10705MBU, GE B50A951, B50A790(403Cb), B50A947A4, B50A947B2, B50A948, B50A789G

Non-Magnetic Steel

Non-Magnetic Steel Drill Collars, Nonmagnetic Stainless Steels, magnetic permeability of μr max 1.01. 1.3813, X40MnCrN19 non-magnetic steels, rust and acid resistant. 1.3813 is often supplied in a hot-cold-formed form.

Special steel & Stainless steel

1.4037, X65Cr13, 65Ch13 ,420D stainless steel is characterised by its high hardenability in conjunction with good corrosion resistance in moderately corrosive environments.

Turbines Maintenance Materials

Chrome Molybdenum Vanadium Steel 21CrMoV5-7/1.7709/1.7707, 31CrMoV9, 40CrMoV4-6/1.7711/B16, X12CrMo5/1.7362/F5/Grade 5 is used for steam and gas turbine components and also for high temperature industrial boilers, valves and oil & gas applications. Bolts, studbolts, nuts, washers, bonet bolts parts of the turbine, pumps, valves etc.

Aerospace

1.4418, X4CrNiMo16-5-1, Z8CND17-04 Martensitic stainless steel have high tensile properties combined with excellent ductility and better corrosion resistance than the common type 400 series martensitics. acc. to EN 4628-2013, AIR 9160/C

Update Steel Grades

Our core focus lies in the production and distribution of steel specifically designed for turbine blades and special applications.

Update Stocked

See what course other students and experts in your domain are learning on.

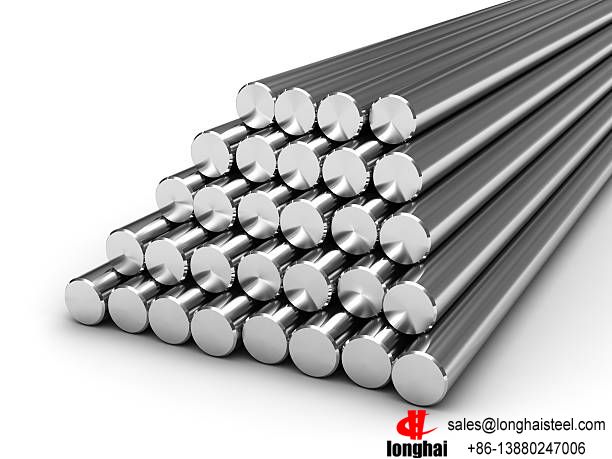

| Grade | Shape | Dimension(mm) | Quantity(PCs) | Weight(Kg) | Condition |

|---|---|---|---|---|---|

| 1Х12Н2ВМФ, ЭИ961 | Round bar | Ф6*2000-3000 | 278 | +C | |

| 36CrNiMo16 | Round bar | Φ130 | 3642 | Annealed | |

| Alloys 800H | Round bar | Φ30 | |||

| 10705BU | Round bar | Φ130x3580 | 1 PCs | 387 | ESR, Ann, Bright |

| X12CrNiMoV12-2 | Round bar | Φ85x3180 | 1 PCs | 146 | Ann, Bright |

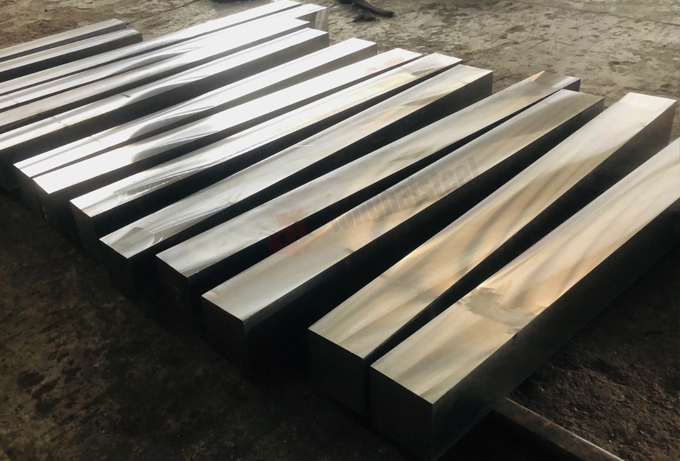

| X19CrMoNbVN11-1 | Forged Bar | 210x210x3000-6000 | 6 | 17769 | QT, Milled |

| XM-25 | Round bar | Φ22 | 207 | SA, Bright | |

| UNS N07718 | Round bar | Φ16 | VIM+ESR, SA, Bright | ||

| X6NiCrTiMoVB25-15-2 | Round bar | Φ40 | SA, Bright | ||

| Nitronic 50 | Round bar | Φ25 to Φ130 | 43123 | ||

| NITRONIC 60 | Round bar | Φ20 | |||

| 34CrMo4 | Round bar | Φ18 | |||

| X22CrMoWV12-1 | Round bar | Φ45 | ESR, QT, Bright | ||

| 1.4534, PH 13-8Mo | Round bar | Φ8.5 | 280 | HC, +S, Bright | |

| 5Cr,0.5Mo | Coil | 0.5*200*C | 710 | CA, | |

| 28NiCrMoV8-5 | Round bar | Φ70 x 4000~6000mm | 27 | 3912 | QT |

| 16NiCr4 | Round bar | Φ26 | 3698 | ESR, QT, Bright | |

| 31CrMoV9 | Round bar | Φ20 | QT, Bright | ||

| 36NiCrMo16 | Round bar | Φ55 | 3346 | EAF+LF+VD, Annealed | |

| 10705MBU | Round bar | Dia.70mm to Dia.150mm | 3988 | +A, Bright |

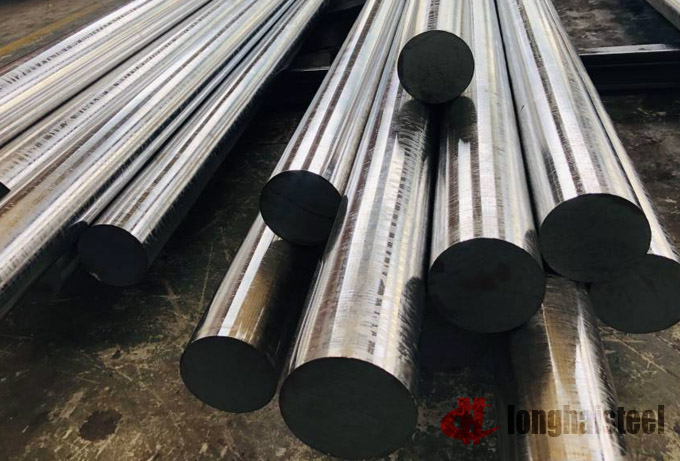

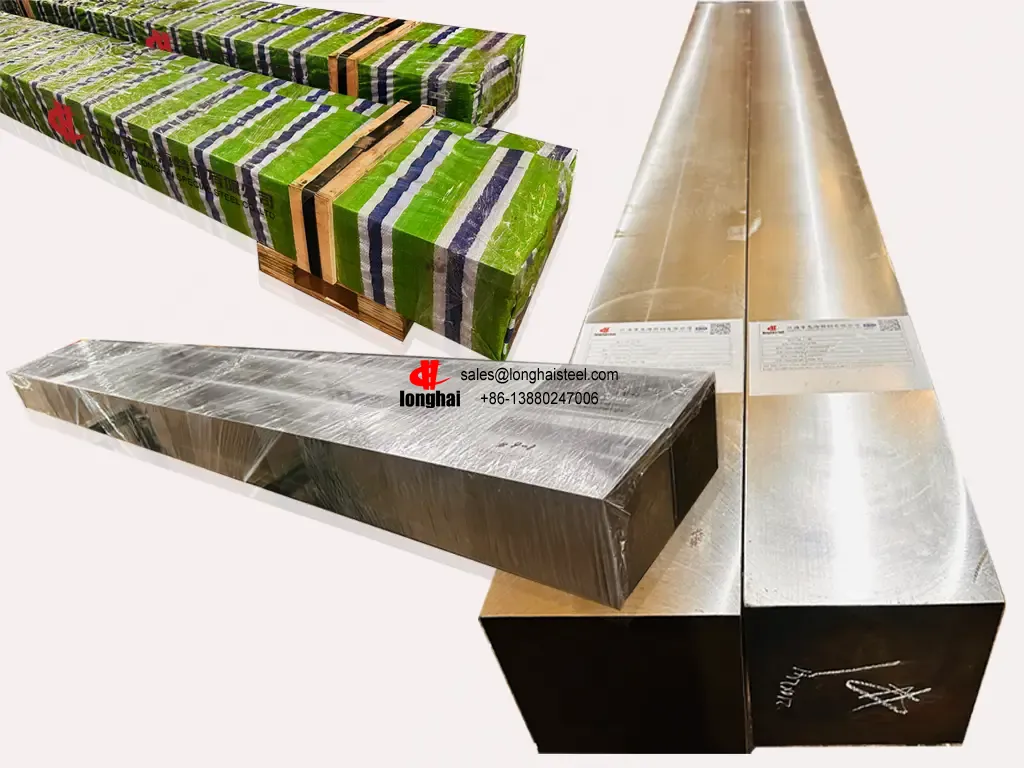

Products

Find steel that are best for your demand.