1.4913, X19CrMoNbVN11-1 high-alloyed chrome-molybdenum Creep resisting martensitic stainless steel, good strength and temper resistance at higher temperatures up to 1200℉, formulated for primary forming into wrought products, Using Bolts, Nuts, Turbine Blades, acc. to EN 10088-1, EN 10302 and EN 10269

- Applications & Details

- Chemical Composition

- Mechanical Properties

- Physical Properties

- Order

- Heat Treatment

- Thermal Properties

- Welding

- Machining

- Similar or equivalents steel grade

What is 1.4913, X19CrMoNbVN11-1 grade steel?

1.4913, X19CrMoNbVN11-1 high-alloyed chrome-molybdenum Creep resisting martensitic stainless steel formulated for primary forming into wrought products, 1.4913, X19CrMoNbVN11-1 high-alloyed chrome-molybdenum Creep resisting steel martensitic stainless steel formulated for primary forming into wrought products, Using Bolts, Nuts, When working at elevated temperatures resistant to 600 ℃, characterized by good resistance and creep limit. 1.4913 is the Numeric designation for this material. X19CrMoNbVN11-1 is the Chemical designation.Other Spec. EN 10269-2006, EN 10302-2008, EN 10269-2013, EN 10088-1-2005, DIN EN 10269-2014

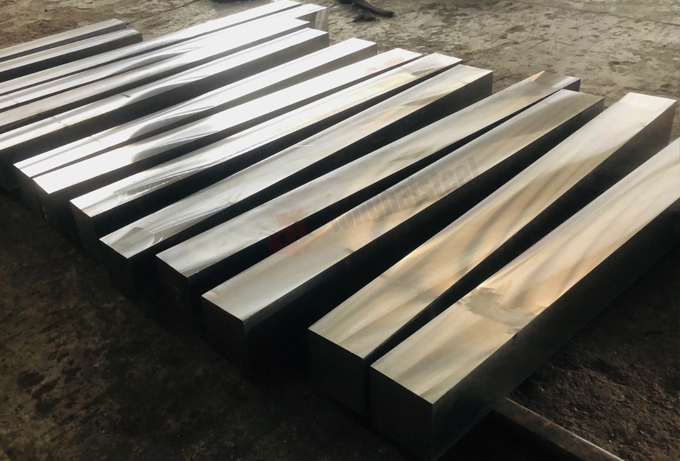

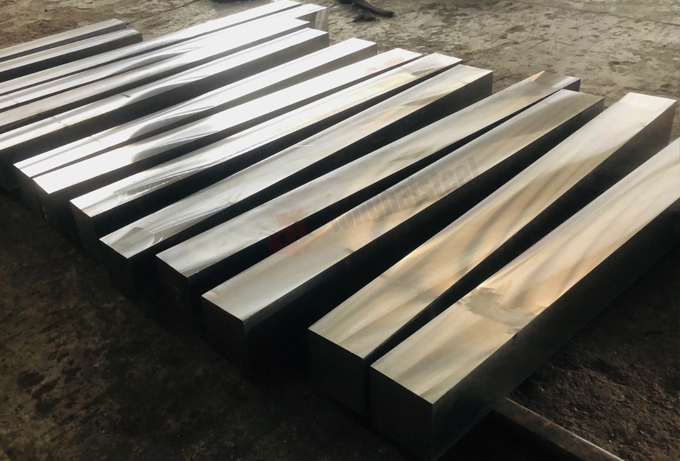

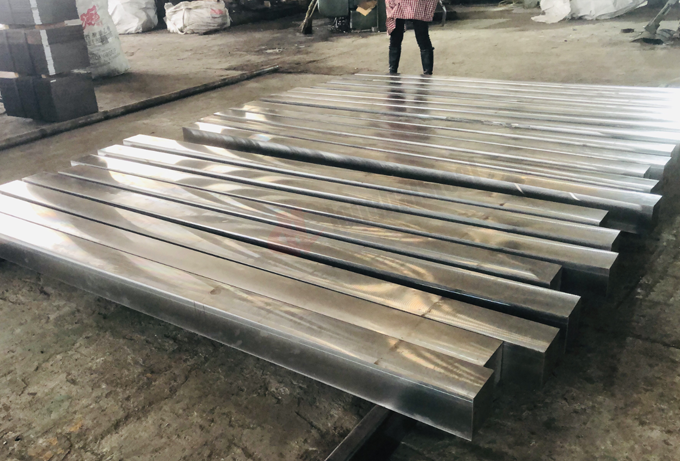

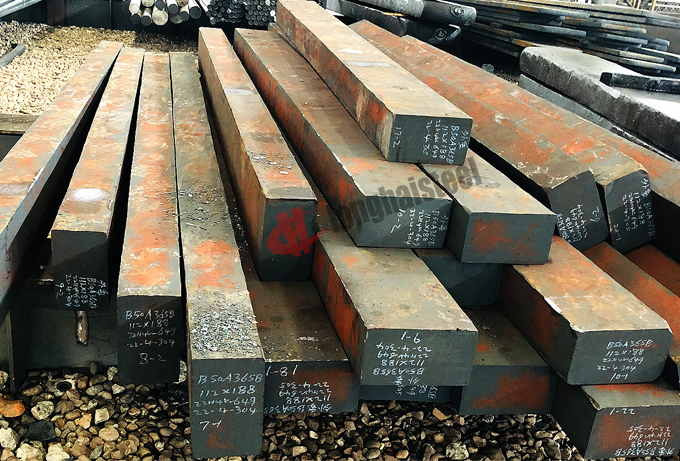

Products Form:

Chemical Composition

| Grade | Chemical Composition % | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | V | Nb | Al | W | B | N | Cu | Ti | ||

| EN 1.4913, X19CrMoNbVN11-1 | 0.17 - 0.23 | 0.4 - 0.9 | Max 0.5 | Max 0.025 | Max 0.015 | 10.0 - 11.5 | 0.2 - 0.6 | 0.5 - 0.8 | 0.1 - 0.3 | 0.25 - 0.55 | Max 0.02 | Max 0.7 | 0.005 - 0.015 | 0.05 - 0.10 | - | - | |

| NF Z20CDNbV11, 56T5 | 0.18 - 0.25 | 0.3 - 0.8 | 0.1 - 0.5 | Max 0.025 | Max 0.015 | 10.0 - 12.0 | Max 1.0 | 0.5 - 1.0 | 0.1 - 0.3 | 0.25 - 0.55 | - | - | - | 0.05 - 0.10 | - | - | |

| NF Z21CDNbV11 | 0.16 - 0.25 | 0.3 - 0.8 | 0.1 - 0.5 | Max 0.030 | Max 0.015 | 10.0 - 12.0 | Max 1.0 | 0.5 - 1.0 | 0.1 - 0.3 | 0.25 - 0.55 | - | - | - | 0.05 - 0.10 | - | - | |

| ISO X18CrMnMoNbVN12, 1.4916 | 0.15 - 0.20 | 0.5 - 1.0 | Max 0.5 | Max 0.040 | Max 0.030 | 10.0 - 13.0 | Max 0.6 | 0.3 - 0.9 | 0.1 - 0.4 | 0.2 - 0.6 | - | - | - | 0.05 - 0.10 | - | - | |

| 18Ch11MNFB, 18Х11МНФБ, 2Х11МФБН, ЕП291 | 0.15 - 0.21 | 0.6 - 1.0 | Max 0.6 | Max 0.030 | Max 0.025 | 10.0 - 11.5 | 0.5 - 1.0 | 0.8 - 1.1 | 0.2 - 0.4 | 0.20 - 0.45 | - | Max 0.2 | - | - | |||

Mechanical Properties

1.4913, X19CrMoNbVN11-1 Mechanical properties acc. to EN 10088-1, EN 10269, EN 10302, Condition +QT

- Tensile strength, Rm: 900 - 1050 MPa

- The yield point, Re: > 750 MPa

- Elongation, A:> 12%

- Contraction, Z: >40%

- Impact resistance, KV20℃: >20J

- Modulus of elasticity, E: 216 GPa

- Thermal capacity, cp20℃: 460 J * kg-1 * K-1

- Thermal conductivity, λ: 24,0 W * m-1 * K-1

- Linear expansion coefficient, α: 10,5 * 10-6 K-1

Thermal Properties

| Properties | Temperature (℃) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | |||

| p0.2 (MPa) | Max 726 | Max 701 | Max 676 | Max 651 | Max 643 | Max 627 | Max 610 | Max 577 | Max 544 | Max 495 | Max 412 | Max 305 | ||

What is 1.4913, X19CrMoNbVN11-1 equivalent to?

1.4916, 17H11MFNb, Z20CDNbV11, Z 20 CDNbV 11, Z21CDNbV11, Z 21 CDNbV 11, MM12G, 4916-600-77-J, X18CrMnMoNbVN12, X 18 CrMnMoNbVN 12, SUH600, F SUH 600, X19CrMoNbVN11-1, X 19 CrMoNbVN11-1, 1.4913, 56 T 5, 56T5, 1.4916, 18Ch11MNFB, 18Х11МНФБ, 2Х11МФБН, ЕП291.