GTD 450 / C450 / UNS S45000 Stainless Steel Overvi

GTD 450 / C450 / UNS S45000 Stainless Steel OverviewGTD 450, also known as C450 or UNS S45000, is a type of martensitic stainless steel renowned for its high strength, excellent corrosion resistance,

C450

November 30, 2024

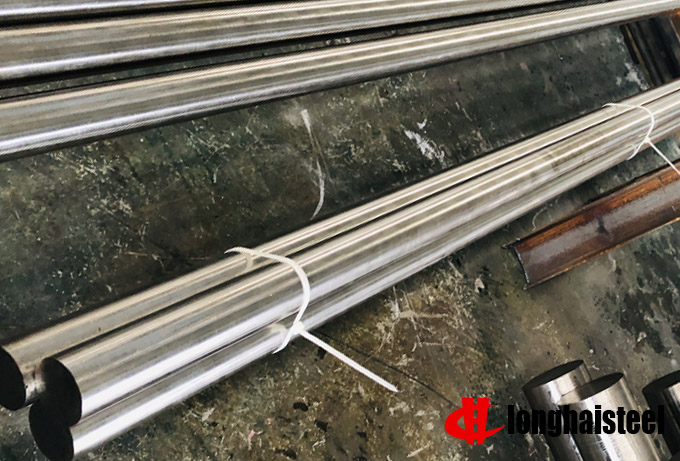

STAINLESS STEEL BAR AND FORGING Cr-Ni-Cu-Cb-Fe ALL

General Electric Material B50A789 identifies a Chromium-Nickel-Copper-Columbium-Iron alloy steel, as forged, extruded or machined, from bar or billet, for compressor blading and steam turbine buckets.

XM-25

October 31, 2024

ASTM A437/A437M Grade B4B Steel

ASTM A437/A437M B4B is a quenched and tempered martensitic stainless steel with excellent mechanical properties

B4B

October 10, 2024

X12CrNiMo12 Bar for highly loaded Blades/Vanes

X12CrNiMo12, 1.4939 QT900 Bar for highly loaded Blades/Vanes

X12CrNiMo12

November 23, 2023

X40MnCrN19 K, 1.3813 cold drawn steel bars

X40MnCrN19 K, 1.3813 cold drawn steel bars for the manufacturing of tension bolts

X40MnCrN19

November 22, 2023

Creep resistant steels - X12CrNiMoV12-2, Z12CNDV12

Creep resistant steels - X12CrNiMoV12-2, Z12CNDV12, 1.4933, 1.4938, 1.4939, S41428, S64152, X12CrNiMo12, XM-32, Jethete M152 comparison, Bar for highly loaded Blades /Vanes (ESR)

X12CrNiMo12

November 20, 2023

St12T, X22CrMoV12-1 Steel bars Creep resistant

NB 00141 Steel bars, Creep resistant, St12T, X22CrMoV12-1, Rp0.2 700 MPa min high alloy steel bars.

X22CrMoV12-1

September 27, 2023

What material is 1.4418?

The material 1.4418 is a stainless steel alloy. It is also known as X4CrNiMo16-5-1 or 1.4418/QT900. This alloy falls under the category of martensitic stainless steel and contains elements like chromium, nickel, molybdenum, and a small amount of sulfur. I

X4CrNiMo16-5-1

September 26, 2023

21CrMoV5-7, 1.7709 Steel for fasteners

21CrMoV5-7 steel has emerged as a highly sought-after material for fasteners due to its exceptional properties and outstanding performance.