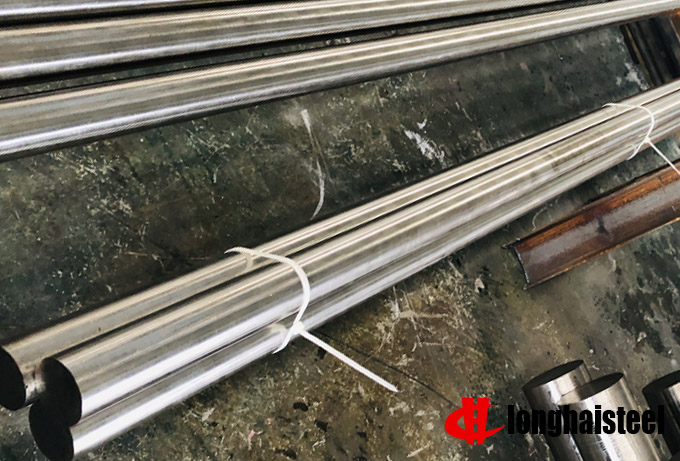

X40MnCrN19 K, 1.3813 cold drawn steel bars

November 23,2023

Scope of Application

- Subject: cold drawn steel bars for the manufacturing of tension bolts

- Material: X40MnCrN19 K

- Material No.: 1.3813

Referenced Documents

- EN 10308, EN 10228-2, EN 10204

Manufacturing

- The bars can either be rolled or forged provided that the requested mechanical properties in cold drawn condition are fulfilled.

Properties and Tests

- Properties and Tests

- Chemical Composition

Heat analysis in weight-%.

| C | Si | Mn | P | S | Cr | N |

|---|---|---|---|---|---|---|

| 0.30-0.50 | max 0.50 | 18.00-20.00 | max 0.05 | max 0.015 | 3.00-5.00 | 0.80-1.20 |

Mechanical Properties

A hardness test shall be performed to verify the uniformity of the strength within a delivery lot (per melt and heat treatment batch). The test amount shall be 10 % of the bars with a minimum of 10 bars. When the lot consists of less than 10 bars all bars shall be tested. The mechanical properties are to be determined for both the hardest and softest bar.

The specimens are to be taken in longitudinal direction out of the center of the bars. The diameter of the tensile specimens shall be 20 mm. The following properties shall be achieved at room temperature:

| 0.2%-proof strength (N/mm2) | tensile strength | elongation | reduction of area | impact energy | hardness HB30 |

|---|---|---|---|---|---|

| min 500 | 850-1250 | min 20 | min 35 | min 90 1) | 260-360 |

Scope of Inspection

Following NDE shall be performed in delivery condition for all bars:

- verification test

- complete ultrasonic inspection (UT) according to EN 10308 type 1a-1c (table 1)

- liquid penetrant test according to EN 10228-2 or according to any other technique that guarantees achieving the requested registration and decision criteria

Criteria for Registration and Decision

UT-inspection:

Regarding UT inspection quality class 3 according to EN 10308 (table 3) The decision limit for loss of back wall echo is 3 dB for all bar dimensions. Every linear or surface-like inhomogenity larger than 10 mm in any direction is not accepted.

Surface crack inspection:

Quality class 4 according to EN 10228-2 (table 1) shall be applied.