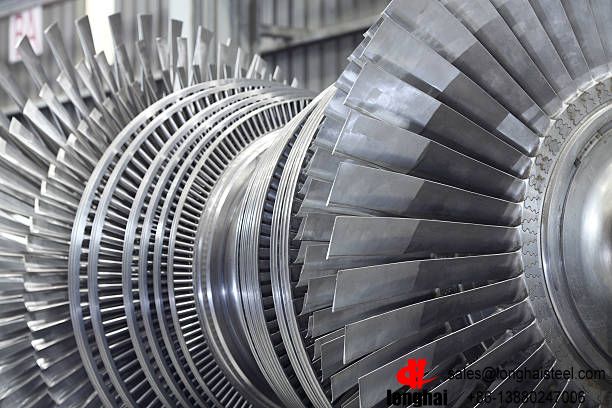

Steel Bars, Stainless, 12% Chromium, for Turbine Application

March 03,2023

This specification identifies hot rolled, heat treated and descaled 12% Chromium, 422-suh-616-b50a951-1-4935-x20crmowv12-1-b4b-steels-of-blade-for-steam-and-gas-turbine" target="_self" title="UNS S42200">UNS S42200 martensitic stainless steel bars, for steam turbine bucket and blade applications at elevated temperatures.Unless otherwise specified, all requirements of ASTM A 565 shall apply.

ASTM Standards: A 565, Martensitic Stainless and Heat-Resisting Steel Bars and shapes

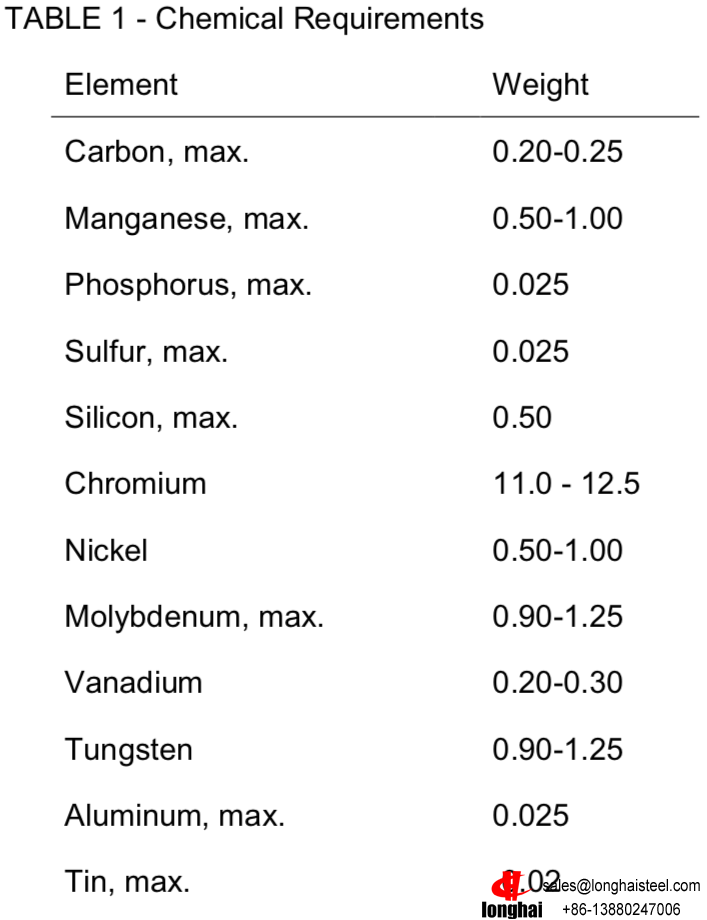

CHEMICAL COMPOSITION

Heat Analysis- Each heat of steel shall meet the Requirements of ASTM A 565, 422-suh-616-b50a951-1-4935-x20crmowv12-1-b4b-steels-of-blade-for-steam-and-gas-turbine" target="_self" title="AISI 422">UNS S42200 as modified in Table 1.

MECHANICAL PROPERTIES

Requirements - Mechanical properties at room temperature shall meet of ASTM A 565, UNS S42200, Condition HT

- Tensile Strength, psi, min. 120,000

- Yield Strength, psi, min. (0.02%) 85,000

- Elongation in 2 in., %, min. 15

- Reduction of Area, % min. 35

- Charpy V-Notch Impact, ft-lb, R min. 15

- Brinell Hardness, max. 285

MANUFACTURE

- Melting Process- Unless the electroslag re-melting (ESR) process is specified on the purchase order, the steel shall be made by the electric furnace process with or without separate refining, such as argon oxygen decarburization (AOD).

- Heat treatment - Bars shall be heated to 1875 - 1925oF, for 2 hours minimum, oil Quenched or air cooled to room temperature, then tempered at 1250oF minimum.

- Stress Relief - Subsequent to any straightening operations, a stress relieving heat treatment at 1100oF minimum is required.

- Finish - All bars shall be furnished in the hot rolled and descaled condition.

MICROSTRUCTURE

Delta Ferrite - Delta Ferrite shall be limited to 5 % of the microstructure.

QUALITY REQUIREMENTS

- Bar Quality - Bars purchased under this specification are intended to be of the best quality with internal soundness and uniform metallurgical structure and properties.

- Vendor is subject to the requirements of TSP-06-03 (TurboCare Approval and Control of Vendors).

- Hardness - Hardness test shall be taken on 10% of the bars in a lot.

- Tension - Two tension tests shalll be randomly selected and tested from each lot. Hardness values of the tension test specimens shall be reported with the tensile data.

- Impact- Two impact tests shall be taken on the same bars selected for the tension test.

- Purchase order number;

- Purchaser's specification number;

- Heat number;

- Chemical heat analysis;

- Mechanical properties including tensile, impact and hardness test results;

- Heat treatment and stress relief, if any, temperatures and times;

- Statement that the material has been manufactured, sampled, tested and inspected in accordance with this specification and the results satisfied the requirements.

NUMBER OF TESTS

CERTIFICATION

Test Report - All tests required by this specification shall be made by the manufacturer and reported on a certificate of test to the purchaser. Each test certificate shall include the following data: