The process of domestication of steam turbine blades

September 26,2023

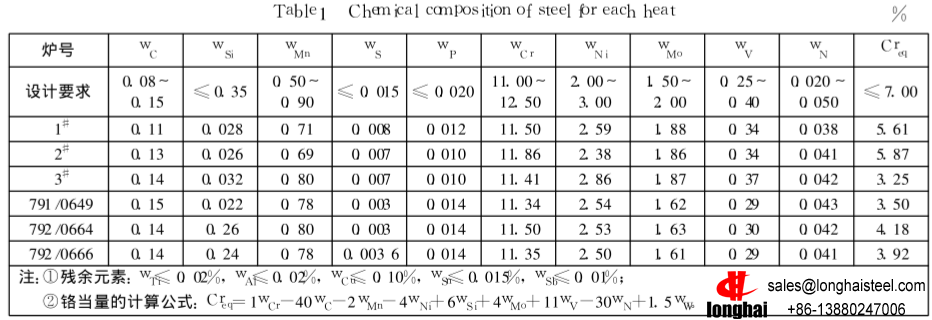

The process of domestication of steam turbine blades in China requires the selection of a suitable heat treatment regime to ensure material performance. Therefore, research has been conducted on the effect of tempering temperature on various mechanical properties during the heat treatment. The results show that the appropriate quenching temperature for this material is 1000℃. Tempering at intervals of 20℃ in the temperature range of 550 to 650℃ is studied in terms of its influence on strength, surface contraction, hardness, and impact power. At a tempering temperature of 580℃, there is no obvious presence of δ-ferrite in the microstructure, and it meets the design requirements of material performance. The materials 1Cr12Ni3Mo2VN, Japanese grade KT5332AS6, British grade S/SJ2, and French grade Z12CNDV12 belong to CrNiMoV martensitic heat-resistant stainless steel, which is widely used in the manufacturing of long blades for 1000 MW ultra-supercritical steam turbine last stages. In recent years, due to the strong demand in the electric power industry, the development of this type of steel has been rapid. However, due to strict requirements on the content of δ-ferrite (≤ 1%), non-metallic inclusions, and performance, it has been necessary to import the material from abroad for a long time. The material composition is based on the smelting process of imported materials, and the experimental materials are produced using the electric arc furnace (EAF) + electroslag remelting (ESR) process. The chemical composition is strictly controlled according to the design requirements, with high requirements for residual element control. Table 1 shows the chemical composition of imported materials and trial-made materials, where "1#", "2#", and "3#" represent specific furnace numbers for the trial-made materials.