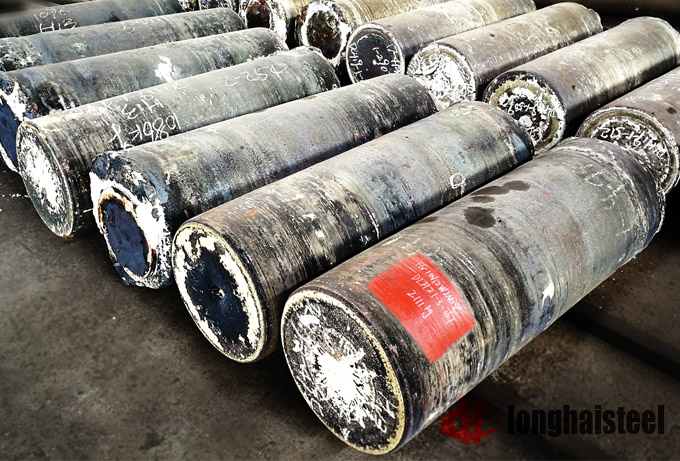

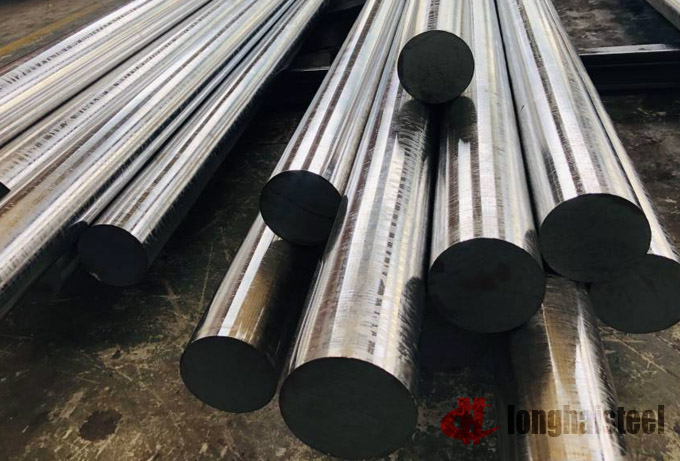

Stock

Stock

1Cr11Ni2W2MoV, 13Cr11Ni2W2MoV, 961 martensitic heat-resistant stainless steel, low-carbon 12% Cr steel added with a large amount of W, Mo, V and other ferrite forming elements that reduce the austenite phase region. acc. GJB 2294-95, GJB 2294A-2014, HB5024-89 and other standards.

- Heat Treatment

- Thermal Properties

- Welding

- Machining

- Similar or equivalents steel grade

What is 1Cr11Ni2W2MoV grade steel?

1Cr11Ni2W2MoV(New grade 13Cr11Ni2W2MoV) steel is a low-carbon 12% Cr martensitic heat-strength stainless steel, adding a large amount of ferrite-forming elements such as W, Mo, V, etc., reducing the austenite phase region, and having strong transformation hardening ability, making the steel have martensitic properties. Physical properties. Its room temperature tensile strength, endurance strength limit and creep limit are all high, and it has good toughness and oxidation resistance; at the same time, the steel has good process plasticity and welding performance, and can manufacture die forgings and welding with complex shapes. Structural parts, suitable for load-bearing parts working under 550 ℃ and high humidity conditions, usually used as tie rods, bolts, sealing rings, bushings, pins, etc. of aircraft engines. GJB 2294-95, GJB 2294A-2014, HB5024 -89 and other standards

Products Form:

Chemical Composition

| Grade | Specification | C | Si | Mn | P | S | Cr | Ni | Mo | V | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1Cr11Ni2W2MoV | GJB 2294 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.025 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 13Cr11Ni2W2MoV | GJB 2294A | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.030 | ≤0.020 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 1Cr11Ni2W2MoV | GJB 2295A | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.025 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 13Cr11Ni2W2MoV | GB/T 1221 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.030 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 13Cr11Ni2W2MoV | GB/T 20878 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.030 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 1Cr11Ni2W2MoV | GB/T 4356 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.030 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 1Cr11Ni2W2MoV | HB 5024 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.035 | ≤0.030 | 10.5-12.0 | 1.4-1.8 | 0.35-0.50 | 0.18-0.3 | 1.5-2.0 |

| 13Х11H2В2МФ, 1Х12Н2ВМФ, ЭИ961 | GOST 5632 | 0.1-0.16 | ≤0.60 | ≤0.60 | ≤0.030 | ≤0.025 | 10.5-12.0 | 1.5-1.8 | 0.35-0.50 | 0.18-0.3 | 1.6-2.0 |

Mechanical Properties

1Cr11Ni2W2MoV Acc. to GJB 2294-95 mechanical properties

- Heat Treatment Process (Group 1) - Normalizing Temperature: 1000-1020℃, Cooling Medium: Oil Cooling or Air Cooling, Tempering Temperature: 660-710℃

- Tensile strength Rm Mpa: ≥885

- Yield point Rp Mpa: ≥735

- Elongation A %: ≥15

- Rate of reduction in area Z %: 55

- Impact energy Aku J: 71

- Hardness:HB 269 - 321

- Heat Treatment System (Group 2) - Normalizing Temperature: 1000-1020℃, Cooling Medium: Oil Cooling or Air Cooling, Tempering Temperature: 540-590℃

- Tensile strength Rm Mpa: ≥1080

- Yield point Rp Mpa: ≥885

- Elongation A %: ≥12

- Rate of reduction in area Z %: 50

- Impact energy Aku J: 55

- Hardness:HB 311 - 388

13Cr11Ni2W2MoV acc. to GJB 2294A-2014 mechanical properties

- Annealed

- Hardness:HB 197-269

- Heat Treatment System (I) - Normalizing at 1000-1020℃, Cooling Medium: Oil or Air, Tempering Temperature: 540-590℃

- Tensile strength Rm Mpa: ≥1080

- Yield point Rp Mpa: ≥885

- Elongation A %: ≥12

- Rate of reduction in area Z %: 50

- Impact energy Aku J: 55

- Hardness:HB 311 - 388

- Heat Treatment System (II) - Normalizing at 1000-1020℃, Cooling Medium: Oil or Air, Tempering Temperature: 660-710℃

- Tensile strength Rm Mpa: ≥885

- Yield point Rp Mpa: ≥735

- Elongation A %: ≥15

- Rate of reduction in area Z %: 55

- Impact energy Aku J: 71

- Hardness:HB 269-321

1Cr11Ni2W2MoV Acc. to GJB 2295 mechanical properties

- Mechanical properties of quenched and tempered martensitic steel plates - Quenching temperature: 1000-1020℃, oil cooling or air cooling, tempering temperature: 660-710℃

- Tensile strength Rm Mpa: ≥835

- Yield point Rp Mpa: -

- Elongation A %: ≥14

- Rate of reduction in area Z %: -

- Impact energy Aku J: -

- Hardness:HB -

13Cr11Ni2W2MoV acc. to GB/T 1221 mechanical properties

- Annealed

- Hardness:HBW ≤269

- Heat treatment(I)

- Tensile strength σb Mpa: ≥885

- Yield point σs Mpa: ≥735

- Elongation δ %: ≥15

- Rate of reduction in area Z %: 55

- Impact energy Aku J: 71

- Hardness:HB 269-321

- Heat treatment(II)

- Tensile strength σb Mpa: ≥1080

- Yield point σs Mpa: ≥885

- Elongation δ %: ≥12

- Rate of reduction in area Z %: 50

- Impact energy Aku J: 55

- Hardness:HB 311-388

1Cr11Ni2W2MoV acc. to GJB 5040 mechanical properties

- Normalized + Tempered or Tempered - Normalized: 990-1010℃, Air;730-750℃ Air cooling;

- Hardness:HBS 197-269

- Quenching temperature:1000-1020℃, OC or AC,

- Tensile strength σb Mpa: ≥1080

- Yield point σs Mpa: ≥885

- Elongation δ %: ≥12

- Rate of reduction in area Z %: 50

- Impact energy Aku J: 55

- Hardness:HB 311 - 388

- Tensile strength σb Mpa: ≥885

- Yield point σs Mpa: ≥735

- Elongation δ %: ≥15

- Rate of reduction in area Z %: 55

- Impact energy Aku J: 71

- Hardness:HB 269-321

- Tempered temperature:660-710℃

- Tempered temperature:540-590℃

1Cr11Ni2W2MoV acc. to HB 5024 Quenching + Tempering mechanical properties

- Quenching temperature:1000-1020℃, Oil or Air,

- Tensile strength σb Mpa: ≥1080

- Yield point σs Mpa: ≥885

- Elongation δ %: ≥12

- Rate of reduction in area Z %: 50

- Impact energy Aku J: 685

- Brinell hardness indentation diameter mm: 3.10-3.45

- Sample blank size: 25mm

- Tensile strength σb Mpa: ≥885

- Yield point σs Mpa: ≥735

- Elongation δ %: ≥15

- Rate of reduction in area Z %: 55

- Impact energy Aku J: 885

- Brinell hardness indentation diameter mm: 3.40-3.70

- Sample blank size:25mm

- Tempered temperature:660-710℃

- Tempered temperature:540-600℃

Physical Properties

| temperature | Elastic Modulus 10- 5 | Linear expansion coefficient a 106 | Thermal Conductivity l | density r | specific heat capacity C | Resistivity R 10 9 |

| Hail | MPa | 1 / Grad | W / (m deg) | kg / m 3 | J / (kg deg) | Ohm m |

| twenty | 2 | 20.9 | 7800 | |||

| 100 | 1.98 | eleven | 22.3 | |||

| 200 | 1.87 | 11.7 | 24 | |||

| 300 | 1.75 | 12.2 | 25 | |||

| 400 | 1.65 | 13.3 | 27.2 | |||

| 450 | 1.57 | |||||

| 500 | 1.45 | 13 | 28 | |||

| 550 | 1.25 | |||||

| 600 | 1.09 | 13.3 | 28.5 | |||

| 700 | 28.9 | |||||

| 800 | 31.4 |

Heat Treatment

General heat treatment

Quenching: 1000-1020℃, Oil Quenched

Tempering: 540-600℃, Air Cooled

Preliminary heat treatment

1Cr11Ni2W2MoV steel blade preparatory heat treatment is heat treatment after forging, the purpose is to eliminate forging defects and stress, improve its structure, promote the solid solution of fully aggregated carbides, and ensure the required mechanical properties (Brinell hardness requirements d=370~430 ). The process specification for preparatory heat treatment is: 850℃ preheating (depending on the installed furnace capacity)+(1000+10)℃ normalizing/air cooling+(740+10)℃ tempering/air cooling or 850℃ preheating+(740+10) ℃ tempering/air cooling.

Final heat treatment

The correct process specification for final heat treatment of 1Cr11Ni2W2MoV steel blade is: 850℃ preheating (depending on the installed furnace capacity) + (1010+10)℃ quenching/oil cooling + (550~570)℃ tempering/air cooling.

1) Quenching 1Cr11Ni2W2MoV steel The higher the quenching heating temperature, the more carbides are dissolved. When heated to 1000 °C, the carbides have been completely dissolved. If the heating temperature is too high, too much S-F will be generated, which will deteriorate the performance of the steel. (mainly the reduction of strength and toughness, fatigue properties and creep properties). Therefore, the quenching heating temperature should be based on the principle of ensuring sufficient austenitization, but only a small amount of -F, and (1000~1020) ℃ is the most suitable. The steel has good hardenability and hardenability, and workpieces <200mm can be hardened. Therefore, for thin-walled parts similar to aero-engine blade blanks, in order to avoid deformation and cracking defects caused by excessive cooling speed, oil-cooling quenching is adopted. The effect is better.

2) Tempering Tempering of 1Cr11Ni2W2MoV steel blades is a very important process, which will have a significant impact on the final mechanical properties. The steel has two tempering brittle zones ((350~530) ℃ and (600~670) ℃), which is the difficulty of the tempering process. The suitable tempering temperature range is very narrow, and a slight deviation will reduce the impact toughness of the steel, so the operation should be very cautious. According to the working conditions of 1Cr11Ni2W2MoV steel blade, the best comprehensive mechanical properties can be obtained by selecting the tempering temperature of 550~570℃.

Thermal Properties

1Cr11Ni2W2MoV, 13Cr11Ni2W2MoV, 13Х11Н2В2МФ, 1Х12Н2ВМФ Steels of Blade for Steam and Gas Turbine stock list

| Steel Grade | Shape | Dimension(mm) | Quantity(PCs) | Weight(Kg) | Condition | Smelt |

|---|

What is 1Cr11Ni2W2MoV equivalent to?

1Cr11Ni2W2MoV, 13Cr11Ni2W2MoV, S47310, 13Х11Н2В2МФ, 13Х11Н2-В2МФ, 1Х12Н2-ВМФ, ЭИ961, 961