Stock

Stock

17-4PH, 1.4542, X5CrNiCuNb16-4, AISI 630, UNS S17400 precipitation hardened stainless steel acc. to TLV9239, 10705 BX, AMS 5604, EN 10088-1, ASTM A564, ABS 5692 D

- Heat Treatment

- Thermal Properties

- Welding

- Machining

- Similar or equivalents steel grade

What is 17-4PH, 1.4542, X5CRNICUNB16-4 grade steel?

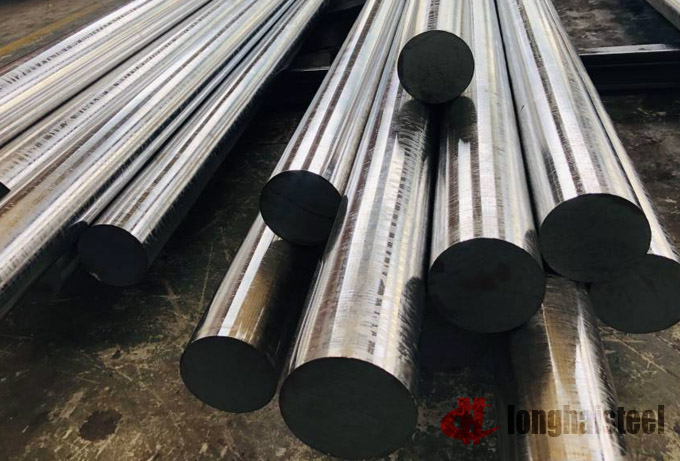

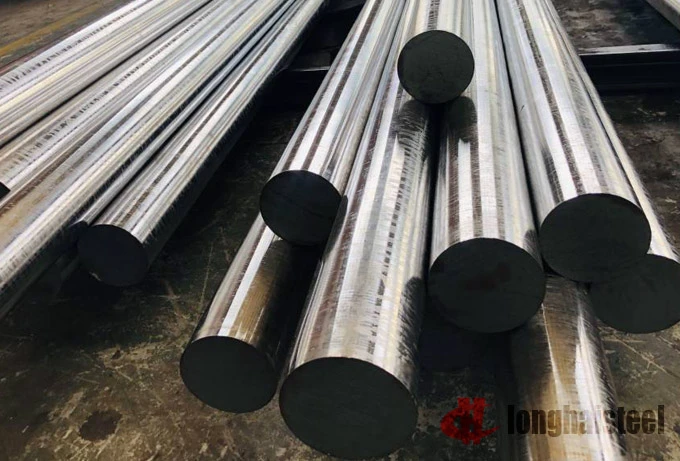

17-4PH is a precipitation hardening stainless chromium-nickel alloy steel with martensitic structure. It has high corrosion resistance and high strength properties. Operates in a temperature range of -59°C to 343°C while maintaining relatively good parameters. In addition, 17-4PH material has better ductility because it is a precipitation hardening steel and should be applied after supersaturation and aging. In delivery condition +A, the product has no martensitic structure, resulting in a significant reduction in corrosion resistance. Steel can be welded by TIG, but the welding process requires the use of annealed material. Otherwise the material at the joint will not maintain the proper structure. Additionally, at the expense of a slight loss of corrosion resistance, the product can be nitrided to obtain a hardened finish. 17-4PH and 1.4542 / X5CrNiCuNb16-4 are available in bar and cold rolled strip in the form of round bars, sheets, flats, etc. The material is widely used in the aerospace, marine, paper, energy, marine and food industries for the manufacture of heavy machine components, bushings, turbine blades, couplings, screws, drive shafts, nuts, measuring devices.17-4ph has good resistance to stress corrosion cracking at higher aging temperatures. acc. to GJB 2294-95, GB/T 8732-2014, AMS 5604, AMS 5343, AMS 5622, AMS 5344, AMS 5643, AMS 5355, AMS 5825, MIL C-24111, MIL P-47183, MIL S-81591

Products Form:

Chemical Composition

| Grade | Chemical Composition WT % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | Mo | Nb | Cu | N | |

| AMS 5604 | Max 0.07 | Max 1.0 | Max 1.0 | Max 0.04 | Max 0.03 | 15.0-17.5 | 3.0-5.0 | Max 0.5 | 5XC-0.45 | 3.0-5.0 | - |

| X5CrNiCuNb16-4, 1.4542 | Max 0.07 | Max 1.5 | Max 0.7 | Max 0.04 | Max 0.03 | 15.0-17.0 | 3.0-5.0 | Max 0.6 | Max 0.45 | 3.0-5.0 | - |

| DIN X4CrNiCuNb16-4, 1.4540 | Max 0.06 | Max 1.0 | Max 1.0 | - | - | 15.0-17.0 | 3.5-5.0 | - | 0.15-0.40 | 2.5-4.0 | Max 0.05 |

| AFNOR Z7CNU17-04 | Max 0.07 | Max 1.0 | Max 0.75 | Max 0.04 | Max 0.015 | 15.5-17.5 | 4.0-5.0 | - | 0.15-0.45 | 3.0-5.0 | - |

| GOST 05Ch16N4D2B, 05Х16Н4Д2Б | Max 0.07 | Max 1.8 | Max 0.8 | Max 0.03 | Max 0.03 | 15.0-17.5 | 2.0-5.0 | - | 0.05-0.5 | 1.5-3.0 | - |

| JIS SUS630 | Max 0.7 | Max 1.0 | Max 1.0 | Max 0.045 | Max 0.03 | 15.0-17.0 | 3.0-5.0 | Max 0.3 | Max 0.45 | 3.0-5.0 | - |

Mechanical Properties

Mechanical properties of UNS S17400 acc. to AMS 5604

- Tensile strength Rm MPa: Min 1276

- Yield Strength Rp MPa: Min 1103

- A %: 3

- Hardness: Max 38 HRC

Mechanical properties of 17-4PH / AISI 630 acc. to ASTM A564

- +A Condition:

- HRC Hardness: <38

- HB Hardness: <363

- H900

- Tensile Strength, Rm: >1310 MPa

- Yield Strength, RP0.2: >1170 MPa

- Elongation, A: >10%

- Area shrinkage, Z: >40%

- HB Hardness: >388

- HRC hardness: >40

- H925

- Tensile Strength, Rm: >1170 MPa

- Yield strength, Rp0,2: >1070 MPa

- Elongation, A: >10%

- Przewężenie, Z: >44%

- HB Hardness: >375

- HRC hardness: >38

- Impact energy, KV21℃: >6.8 J

- H1025

- Tensile Strength, Rm: >1070 MPa

- Yield strength, Rp0,2: >1000 MPa

- Elongation, A: >12%

- Area shrinkage, Z: >45%

- HB Hardness: >331

- HRC hardness: >35

- Udarność, KV21℃: >20 J

- H1075

- Tensile Strength, Rm: >1000 MPa

- Yield strength, Rp0,2: >860 MPa

- Elongation, A: >13%

- Area shrinkage, Z: >45%

- HB Hardness: >311

- HRC hardness: >32

- Impact energy, KV21℃: >27 J

- H1100

- Tensile Strength, Rm: >965 MPa

- Yield strength, Rp0,2: >795 MPa

- Elongation, A: >14%

- Area shrinkage, Z: >45%

- HB Hardness: >302

- HRC hardness: >31

- Impact energy, KV21℃: >34 J

- H1150

- Tensile Strength, Rm: >930 MPa

- Yield strength, Rp0,2: >725 MPa

- Elongation, A: >16%

- Area shrinkage, Z: >50%

- HB Hardness: >277

- HRC hardness: >28

- Impact energy, KV21℃: >41 J

- H1150M

- Tensile Strength, Rm: >795 MPa

- Yield strength, Rp0,2: >520 MPa

- Elongation, A: >18%

- Area shrinkage, Z: >55%

- HB Hardness: >255

- HRC hardness: >24

- Impact energy, KV21℃: >75 J

- H1150D

- Tensile Strength, Rm: >860 MPa

- Yield strength, Rp0,2: >725 MPa

- Elongation, A: >16%

- Area shrinkage, Z: >50%

- HB Hardness: >255

- HRC hardness: >24

- Impact energy, KV21℃: >41 J

Physical Properties

Grade | 3) | Elastic Modulus | Mean Co-eff of Thermal Expansion (µm/m/°C) | Thermal Conductivity | Specific Heat 0-100°C | Elec Resistivity | |||

0-100°C | 0-315°C | 0-538°C | At 100°C | At 500°C | |||||

630 | 7750 | 197 | 10.8 | 11.6 | - | 18.4 | 22.7 | 460 | 800 |

Heat Treatment

17-4PH stainless steel is immersed at 1038°C (1900°F) for 30 minutes, then cooled to below 16°C (60°F) to fully transform martensite in Condition A. Condition A material was treated at 482°C (900°F) for 1 hour, then cooled. Solution-treated materials were soaked for 4 hours under H925, H1025, H1075, H1100, and H1150 conditions at specified temperatures, and then air-cooled. Solution treated material was immersed at 760°C (1400°F) for 2 hours under H1150M conditions and then cooled. Heat again at 620°C (1150°F) for 4 hours, then cool.

Welding Properties

17-4PH stainless steel can be welded using common fusion and resistance welding methods. The oxyacetylene welding method is not the preferred method for welding this alloy.

Machining Properties

17-4 stainless steel can be machined in the annealed condition, this alloy has long, sticky pieces that require post-working solution treatment before final hardening if machined in H1150M condition.

17-4ph, X5CrNiCuNb16-4, AISI 630, S17400, 1.4542, 1.4548.4 Steels of Blade for Steam and Gas Turbine stock list

| Steel Grade | Shape | Dimension(mm) | Quantity(PCs) | Weight(Kg) | Condition | Smelt |

|---|

What is 17-4PH, 1.4542, X5CRNICUNB16-4 equivalent to?

630, S17400, 1.4542, X5CrNiCuNb16-4, SUS 630, 05Cr17Ni4Cu4Nb, UNS S17400, X5CrNiCuNb16-4, 1.4542, 17-4PH, AMS5643, 10705BX, GTC-005, 630, AMS5622, 10705GE, ASTM A564 GRADE 630, 10705GV, ASTM A484